Know About Power Tongs And Their Various Uses

Hydraulic power tongs are employed to lessen the drill time and lower costs. They are made for safe and quick makeup and break-out drill pipes and drill collars.

They are widely used to make or break casing tubular. It is situated in the drill gap to maintain the well’s opening. Available with various models to choose from Standard, Hydra-Shift, High Torque, and Ultra High Rpm with torques varying from 15, 1000 ft-lbs up to 200 000 ft-lbs. Once the covering is installed, the tube is inserted inside the casing, from the opening well at the top to the development at the base. The hydrocarbons that are extracted run up this tube to the surface.

The benefit for these automated casing working and tubular managing systems was leveraged by many other innovations. Modular systems provided interchangeable mechanical power tongs for the casing, tubing, and drill pipe. Multitask flexibility combined the capacity to execute casing link makeup, torque supervising, casing fill-up and circulation, rotation and case reaming and drilling, and elevator functions.

These tongs are equipped for re-writing the pipe upward and, at times, can apply the ultimate makeup torque. Many types of Strength Tongs can be used based on their specific use:

Power Tongs are self-locking, large-capacity pliers used to grip the drill string components and apply torque. A plumber should use the tongs in opposing sets with opposing tube wrenches. The tongs are tied off with a string or a cable connection to the derrick to increase efficiency, and the other group is taken actively with mechanized catheads. The Strength Tongs are either hydraulically or pneumatically operated tools.

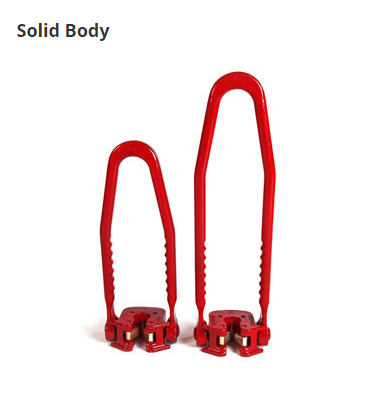

PowerTongs provide reliable performance even at higher torque turn systems necessary to split premium connections. These types are coupled with Safety Clamp Type T, ensuring reliability, minimum maintenance, and quick operator turn-out.

Comments

Post a Comment