Tubing, Casing, and Single Joint Elevators: Know How to Use Different Elevators

Elevators play a very critical role in the oil and gas industry, mainly being utilized in the process of elevating and lowering heavy pipes to aid in drilling processes. Different types of elevators have different functions in each category. The ones with topmost priority include Tubing Elevators, Casing Elevators, and Single Joint Elevators. Let's begin learning each one.

What Are Tubing

Elevators?

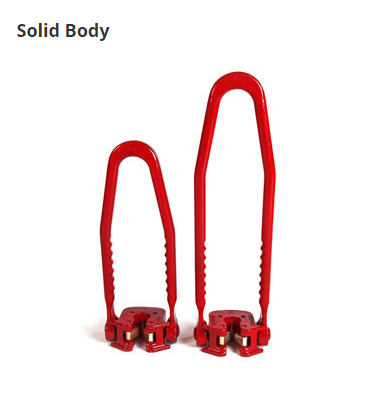

Tubing Elevators are the ones designed to lift and carry tubular materials during the time of operation in the oilfield. These elevators have strong construction in case the tubing is being used for lining wells, because of the weight that comes with it. Tubing Elevators are utilized in assisting the running or pulling of the tubing during the different operations of drilling, cementing, or production. They make safe and efficient lifting of heavy pipes. It can also work in tough environments.

The role of casing elevators in drilling operationsSimilar to Tubing Elevators, Casing Elevators are used to handle larger diameter pipes, which are also known as casing pipes, very important for keeping the integrity of the wellbore. These elevators are designed with a larger gripping capacity to secure the casing while it is being lowered or retrieved. Casing elevators are essential in both onshore and offshore drilling operations for the smooth and safe handling of casing during well construction. They come in various designs depending on the particular weight and size of the casing used in the project.

Single Joint Elevators:

Handling Large Sections Efficiently

Single Joint Elevators are specifically designed to lift single joint sections of tubing or casing. It is usually done in a joint length. The elevators are helpful when long sections of pipe are installed or removed and continuous and smooth operation is required. Single Joint Elevators offer more stability while lifting, thus less likely to cause accidents or damage to equipment.

Why These Elevators Are

Necessary

Each type of elevator, including Tubing Elevators, Casing Elevators, and Single Joint Elevators, plays a role in drilling operations. These are used to lift and handle different sizes and types of pipes safely while meeting the operational timelines. It reduces downtime, prevents accidents, and ensures well integrity is preserved during the drilling process by applying the right elevator for each job.

It's in conclusion that an elevator should be chosen specifically for the task at hand in any drilling operation. Improvement in safety, efficiency, and operational success in a drilling project can be foreseen with the right equipment.

Comments

Post a Comment