Discover the Tubing Elevators Online

Understanding the action of the wellbeing clip Varco will cause you to fathom the justification behind a security brace. Why do we use it in our ordinary system on the drill floor, whether or not we run Drill Pipe, Casing, or Tubing?

Whenever the tubing elevators group starts running the fundamental lines in the opening, little weight is moved to the slips. At the point when weight extends, the slips will set even more determinedly with a more intense bite on the line. With little line weight in the slips, they are not chewing the line sufficiently, and there is a risk of slippage.

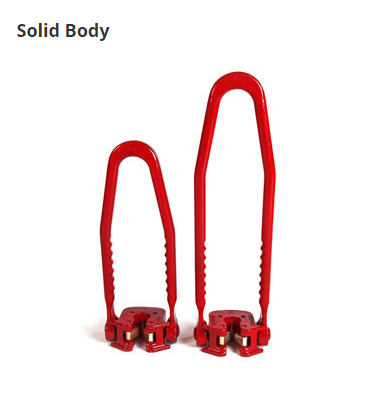

Here the security support enters the scene. It is a device created of parts with spring stacked. Right when the line is sneaking in the slips, the security snap will ingest the impact on the most noteworthy reason behind the slips compelling them more significant in the turning, hindering the line to drop down the opening. Tubing elevators are a safeguarded and invaluable instrument to thwart dropping smooth drill collars or flush joint lines into the opening while simultaneously making up or breaking out the string. Other notable purposes are fuse use while running tremendous estimation surface packaging, treatment of exhausting risers and packaging heads during foundation, and lifting prepacked stone liners.

Rod elevators contain individual associations, deftly turned together. Every association has an alternate fixed slip which goes probably as a holding part, like a fixed pivoting slip, and each slip is stood firm on in a removed balance on the shape by spring strain.

● Right when the clasp is fixed, every last slip takes a firm starting to hang outwardly of the line.

● Expected to work on the viability, and security of drill floor exercises, drill pipe power utensils are major gadgets in the oil and gas industry. They are gigantic cutoff points, self-locking forces used for applying power, and holding drill string fragments.

● Rod elevators expected to make up the packaging string are checked and controlled to ensure that the packaging string doesn't spill.

● It makes a turning development while breaking out, or making up housings, tubings, drill pipes, and various lines. The make-up force examinations rely upon packaging size, grade, metallurgy, weight, and it is accustomed to string compound grinding components.

Comments

Post a Comment