Usefulness of Quality Dies, Inserts and Type C Safety Clamps

Regarding any drilling rig, safety comes first, and running expenses are second in importance. Every second is crucial when a rig is working, and every tiny detail is critical. The efficiency of your process and the longevity of your equipment both improve when you utilize high-quality tools and equipment. The consequences may be severe if even the simplest or smallest component fails. Using generic dies and inserts may save you money, but the price you'll pay if they break during drilling is undoubtedly not worth the savings.

Dies

For oil rig tubing tongs to grab tool joints without causing damage, dies are required to aid in removing or running in tubular. A dies and insert or "insert" is a common name for this kind of die, although it should not be confused with the bit inserts that will be covered shortly.

Different dies must be utilized depending on whether power tongs or manual tongs are used, as well as the size and tolerance variances. Choosing the correct die for your extraction equipment is essential.

Inserts

It is sometimes termed as "slip insert" or "bit insert." Different bits, stabilizer blades, and reamer cutter inserts have different shapes and sizes. Tungsten carbide is a common material for insert bits, which are designed to withstand wear and fracture under even the most extreme pressure. Corrosion-resistant coatings are also used. The rate of penetration of your drill should be maximized with quality inserts, and the inserts should last for a long time.

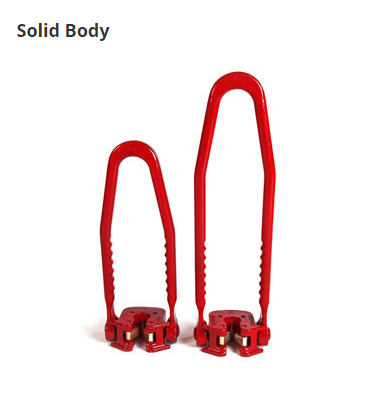

Type C Safety Clamp

On the rig floor, the Type C Safety Clamp is a must-have item. The Safety Clamp Type C comprises a series of flexible links. In each link, a spring-loaded insert is inserted into a tapered slip. Like a sharp rotating drop, the association works as a grasping component.

When the link is tightened, each connection grips the tubular's surface firmly. When the pipe begins to fall or the load on the slip increases, the tapered inserts wedge closer against the line to stop further movement.

Type C Safety Clamps are available in a broad range of designs at MOT. State-of-the-art CNC machines at MOT produce precision-machined dies and inserts that meet exacting standards. Afterward, the inserts are heat-treated for optimal life and durability. Order now!

Comments

Post a Comment