Optimising Midland Oil Tools' Torque Turn Systems, Dies, and Inserts

When it comes to finding and producing oil and gas, speed and accuracy are very important. Midland Oil Tools (MOT) is a trusted name in the business world, and they focus on making new tools and goods for the drilling, completion, and well service sectors. The company has a wide range of products, but their torque turn systems, dies and inserts are very important for making sure that agricultural equipment works smoothly.

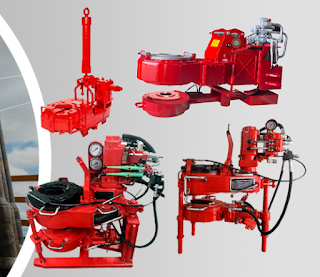

Torque Turn Systems: Reliable Operations' Backbone

When it comes to oil and gas, MOT's torque turn systems are the key to reliable operations. These systems are made to apply just the right amount of force for different drilling and finishing jobs. MOT's torque turn systems are the most accurate on the market in a field where accuracy can mean the difference between success and failure.

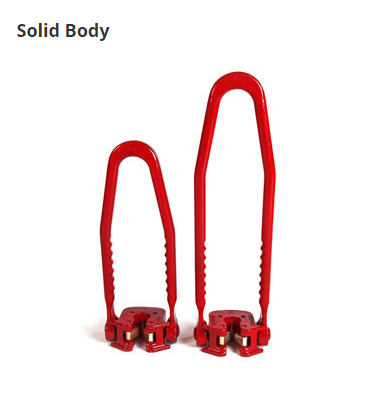

Maintaining Quality and Durability: Dies and Inserts

People who work with drilling tools every day don't give dies and inserts enough credit. These parts are very important for keeping the wellbore intact and are needed to shape and join pipes. The dies and inserts made by MOT are carefully designed to work in oil and gas activities, which can be very rough.

For long times of use, these parts will stay together because they are made with high-quality materials and precise manufacturing methods. Because these things last longer, MOT's clients save money and have less downtime. MOT's dedication to quality makes all the difference in a field where equipment dependability is very important.

Performance and efficiency maximization

In the oil and gas business, efficiency is very important. The dies, plugs, and torque turn systems from MOT all work together to get the best results. By making sure that the torque is applied correctly and regularly, you can keep equipment from wearing out too quickly, which means that it won't need to be replaced or fixed as often.

These wellbores are also more structurally sound because of the precise threading that MOT's dies and plugs provide. In turn, this improves the general performance of the drilling and completion processes, which leads to higher yields and lower costs.

Finally, Midland Oil Tools is committed to providing cutting edge solutions to the oil and gas business. Their torque turn systems, dies, and inserts are proof of this. As the well service, drilling, and finishing industries change, MOT will be there to help make sure that oilfield operations are successful and last. Because they are made to be precise and last a long time, MOT's goods are essential for oil and gas exploration and production that is both high-performance and efficient.

Comments

Post a Comment