Essential Mud Pump Parts for Optimal Performance

Mud pumps are of utmost necessity in drilling. They are responsible for the circulation of drilling fluid, stabilize wellbore and carry cuttings out. A proper set of components from one-shot spare parts to rugged fluid-end parts of mud pumps enhances the operational efficiency of these pumps at any time. These components regulate pressure, eliminate the possibility of system downtimes, and ensure that the rigs will keep going as required; thus, all of them are equally important in a mud pump, be it one-shot spare parts or rugged fluid-end parts.

Using high-standard mud pump parts is an integral part of any drilling operation. Mud pumps are under extreme stress in drilling operations. With years of the pumping of high-pressure, abrasive fluid and constant use, these parts have been subjected to extreme wear. Quality alternatives ensure the replacement of those worn-out parts into active duty right hand away, avoiding unnecessary and costly internment repairs.

Mud pump component standards include pistons, liners, valves, seals, gaskets, and seals. They are all essential in the creation of the pressure, which also acts to stop leaks within the system. More rugged materials, like ceramic liners and high-performance rubber pistons, guarantee a longer service life and increased efficiency throughout the pump.

Understanding Pump Fluid End Parts

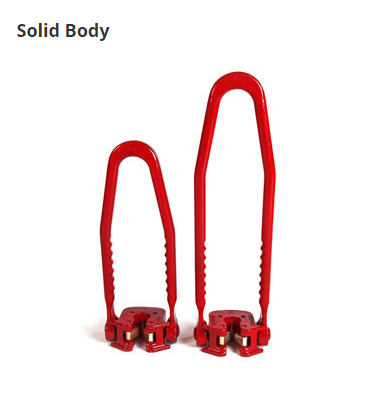

The most sensitive component of a mud pump is the fluid end, which is engaged in the high-pressure displacement of the drilling fluid. The assembly comprises modules, retainers, plungers, and valve covers under intense operational loads.

Good pump fluid end parts maintain the pump performance by ensuring smooth fluid transfer, thus avoiding malfunctions. Effective inspection and replacement of the same within time are important factors in avoiding unexpected shutdown and equipment damage at very high costs.

Choosing the Right Parts for Your Mud Pump

Selecting the right components for your mud pump relies on numerous aspects, including compatibility, material durability, and functional needs. OEM and quality aftermarket components ensure ultimate performance and long lifespan. Go for manufacturers with precision-engineered components designed to withstand the harshest drilling conditions.

Optimize Efficiency with Trustworthy Mud Pump Components

A well-maintained mud pump means smoother drilling, increased efficiency, and less maintenance cost. It could be mud pump parts or fluid end pump parts; the best parts are what you need to keep your drilling system in the best working condition. Maintenance, regular replacements, and the use of durable parts keep your equipment running efficiently, making your operations productive and affordable.

Comments

Post a Comment