Bucking Units vs. Breakout Machines: Choosing the Right Tool for Pipe Torque Applications

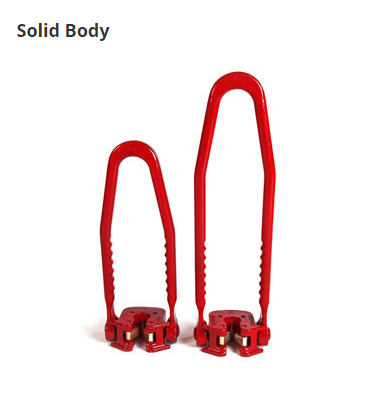

What Are Bucking Units and How Do They Work?

Bucking units are powerful torque

devices for tightening or loosening threaded connections on oilfield tubulars.

Before they leave the shop or rig to go to the field, these tools are typically

set up in shops or rigs to assemble tool joints, drill pipes, or collars, or

even to put together MWD or LWD tool strings. Their hydraulic clamping tools

are highly precise, and repeated use is important for safe, reliable well

performance.

Breakout Machines: Key Functions and Field Use

The main purpose of breakout machines

is to release pipe connections that are too tight, jammed, or over-torqued.

They are useful in the field when you need to rapidly and safely break down

tools and pipelines. They are also often used during disassembly or

maintenance. Breakout machines are sometimes available in portable forms, which

makes them an excellent alternative for jobs that need to be done on-site.

Differences in Torque Control and Speed

Torque control is one of the primary

distinctions between bucking units and breakout machines. Bucking units are

made for accuracy and provide you with accurate torque settings so you can get

the same results every time. Breakout machines are better at undoing tough

joints because they have greater raw force. Breakout machines may work faster

in the field, but bucking units

offer more regulated performance that is preferable for shop usage.

When to Choose a Bucking Unit Over a Breakout Machine

If you require exact makeup torque

and are preparing equipment in a controlled setting, bucking units are the

ideal choice. Breakout machines are better for field service work or repairs

that require loosening tough connections. Where and how you're working will

help you choose the right one.

Setup Considerations for Safe Operation

Both systems need a reliable setup

and skilled staff to keep things safe. Because they are big, bucking units need

a special installation space with the right support. Before you operate a

breakout machine, especially a portable one, it has to have a stable base and

the right hydraulic connections.

Cost vs. Efficiency: Which System Delivers More Value?

Because they have more precise

functions, bucking units normally cost more up front. But they are worth more

in the long run if you use them all the time. For transportable or infrequent use,

breakout machines can be a better deal. In the end, what you need will help you

decide which is the best investment.

Are you looking for bucking units or

breakout machines that work well and are reliable?

Midland Oil Tools (MOT) makes equipment that has been tested in the field and is engineered to handle the toughest jobs in the industry. MOT makes sure that all of its products are safe, high-quality, and work well, from precision torque systems to tough breakout machines. Go to MOT now and get tools that work as hard as you do.

Comments

Post a Comment