Hydraulic and Sucker Rod Power Tongs Improve Drilling Efficiency

The oil and gas business needs strong, safe, and precise drilling gear. Every second counts, and the correct equipment may enhance efficiency and reduce downtime. Hydraulic power tongs and sucker rod power tongs are reliable tools on rigs. In high-pressure environments, these devices simplify pipe handling, secure connections, and improve operator safety. Midland Oil Tools (MOT) continues to offer tough, reliable solutions for current drilling operations.

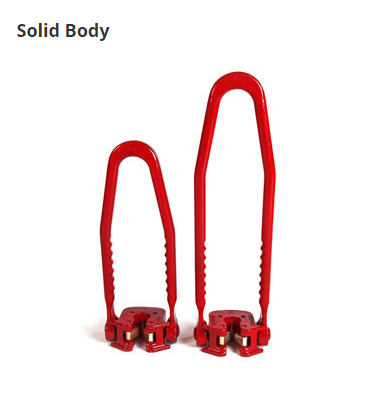

Hydraulic Power Tongs in Oilfield Operations

Hydraulic systems have strengthened essential oilfield processes. On drilling rigs, hydraulic power tongs make or break tubular connections. Their design controls torque application, reducing cross-threading and pipe damage.

Key Features of Hydraulic Power Tongs

The innovative engineering of hydraulic power tongs makes them efficient. The gripping force and hydraulic pressure make them appropriate for heavy-duty activities. Torque monitoring systems in modern models let operators check every connection for industry standards.

Compact frames and customizable designs make them adaptable to diverse rig arrangements. Rapid jaw shutting reduces handling time, while safety guards and anti-slip jaws protect. These features boost performance and make operations safer.

Why Modern Rigs Need Hydraulic Power Tongs

Rig operators know reliability is crucial in severe environments. By offering consistent results, hydraulic power tongs avoid drilling equipment failure and associated delays. Strong teams can handle high-torque applications without manual strain, keeping projects on schedule.

Oilfield Uses of Sucker Rod Power Tongs

Beyond drill pipes and casing, operators must handle sucker rods efficiently. Automating sucker rod string installation and removal in pumping wells with sucker rod power tongs is the perfect answer. Their involvement is crucial for productivity and seamless artificial lift operations.

Benefits of Sucker Rod Power Tongs

Using sucker rod power tongs on oilfields has various benefits. First, they reduce manual force, improving safety. Second, their design regulates torque to prevent rod damage and prolong equipment life.

Comparison of Hydraulic and Sucker Rod Power Tongs

Both instruments apply torque, but their roles differ. Drill pipes and casing require tremendous torque; therefore, hydraulic power tongs are perfect. Smaller rod connections are handled by sucker rod power tongs, which prioritise speed and safety during well maintenance.

They offer a complete drilling and production solution. Their joint use lets operators drill and pump safely and efficiently.

Modern Power Tongs' Safety Benefits

Safety is paramount in oilfield operations. Both hydraulic power tongs and sucker rod power tongs lessen risks in high-pressure tasks by decreasing manual intervention. Remote controls, torque monitoring, and guarded jaws minimise accidents and improve precision.

These tongs protect crews and promote safer drilling by decreasing human involvement in dangerous activities. Their integration into daily operations shows the industry's dedication to worker safety and performance.

How Advanced Power Tongs from MOT Help the Industry

Midland Oil Tools (MOT) develops drilling solutions to satisfy changing needs. MOT builds hydraulic power tongs and sucker rod power tongs for dependability, safety, and efficiency with decades of experience.

Every unit is precision-engineered, rigorously tested, and built to serve personnel in the toughest circumstances. MOT equipment improves performance and decreases downtime by combining innovation and industry knowledge.

Conclusion

Both hydraulic power tongs and sucker rod power tongs play crucial roles in efficient and safe operations. They simplify connections, boost safety, and ensure drilling and output. Midland Oil Tools (MOT) leads the way with durable, high-performance solutions for modern oilfields.

Comments

Post a Comment