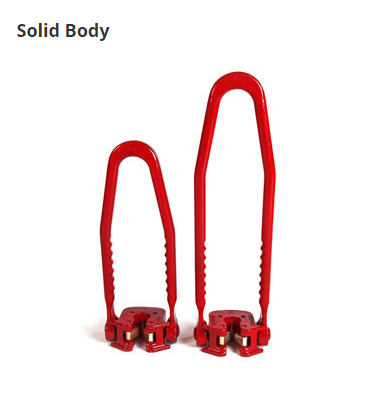

Reliable Drill Pipe Rotary Slips and Varco Slips with Durable Rotary Slip Parts

Strong tools, capable of handling heavy loads and operating in rough environments, are essential for drill pipe work. Drill pipe rotary slips and varco slips are some of the most reliable handling tools that can be applied in the drill environment and whose supporting rotary slip parts make them work over years. These are essential for ensuring safe gripping and preventing interference with the pipes on rig floors.

Drill Pipe Rotary Slips for Secure Tubular Gripping

Drill pipe rotary slips are made to hold tubulars in the running and pulling modes. You can engage the rotary table so that its tapered shape and hardened inserts facilitate an effortless transition. The correct design minimizes the damage of pipes, enhances safety, and assists crews to provide a stable workflow. The drill pipe rotary slips also allow a variety of sizes, which makes them useful in different drilling programmes.

Varco Slips Design and Performance in Drilling Operations

Varco slips are known for their robust construction, balanced weight, and extended durability. Their engineering aims to distribute the load correctly and maintain a consistent gripping strength. Varco slips also facilitate the process of preventing pipe slippage and decreasing handling concerns in rigorous drills. The design also encourages quicker installation and removal, which may enhance rig floor effectiveness and cause less downtime in operation.

Choosing the Right Rotary Slip Parts for Long Service Life

High-quality rotary slip parts are crucial for long-term performance. Handles, pins, inserts and segments must be compatible with the slip body and made out of powerful materials. The selection of appropriate rotary slip parts will ensure an increased life cycle, a high level of grip, and low maintenance costs. They also need to be compatible with drill pipe rotary slips and varco slips, which allow them to work properly.

Maintenance Tips for Drill Pipe Rotary Slips & Varco Slips

Cleaning and regular checks enhance safety in the area of operation. Crews are to look at inserts to ensure their wear and maintenance hinge points are oiled and broken rotary slip parts exchanged as soon as they are damaged. Preventive care is used to make sure that the drill pipe rotary slips and varco slips perform their functions safely and easily when drilling.

Safety Standards for Rotary Slip Parts in Rig Handling Tools

The safety codes do dictate that the handling of tools should be up to performance and material standards. Enabling safer working at the rig floor through the usage of approved rotary slip parts and proper maintenance of drill pipe rotary slips and varco slips.

To find reliable drill pipe rotary slips, varco slips, and exemplary rotary slip parts, look at the tried and true products that are offered by Midland Oil Tools (MOT) and find out how they can be used to assist safer and more efficient drilling work.

.jpg)

Comments

Post a Comment